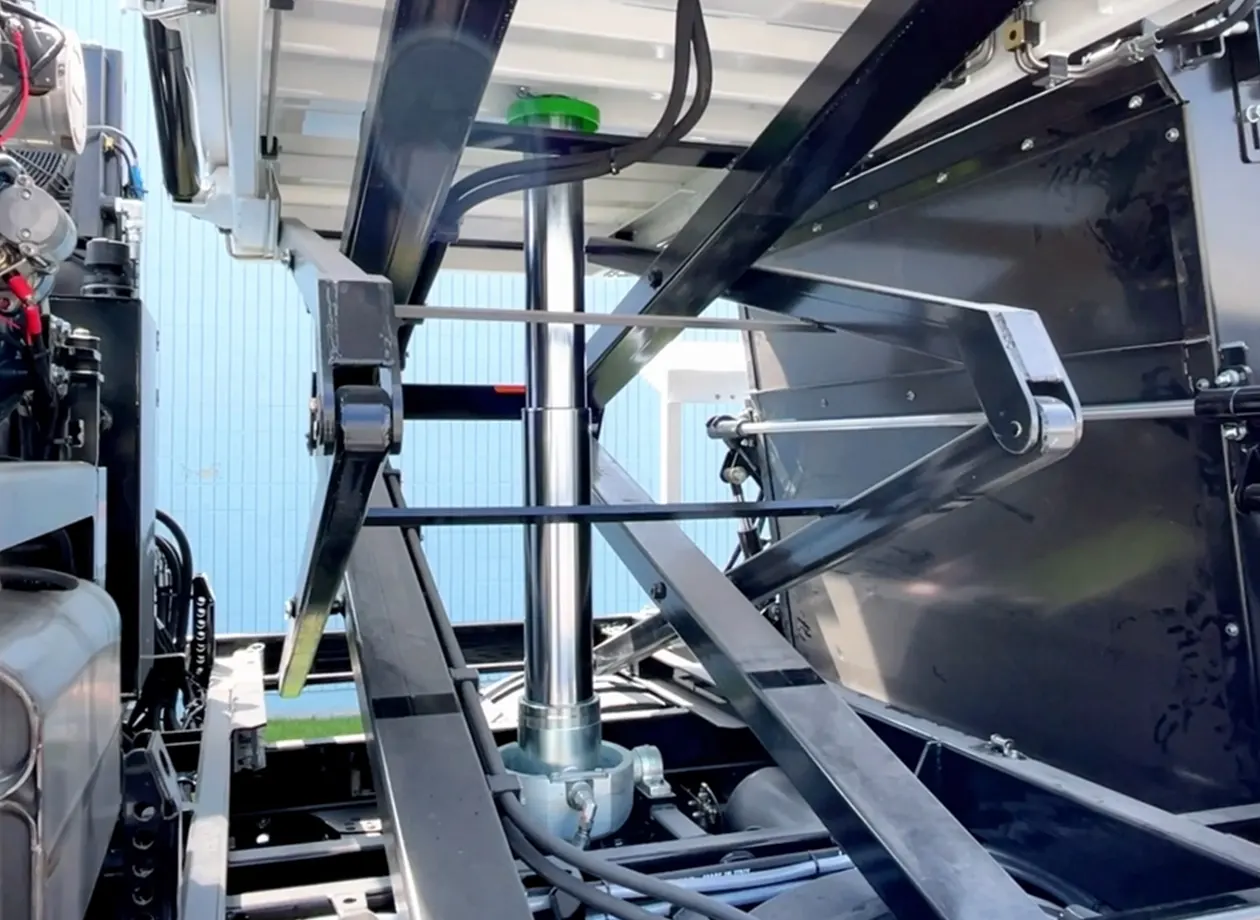

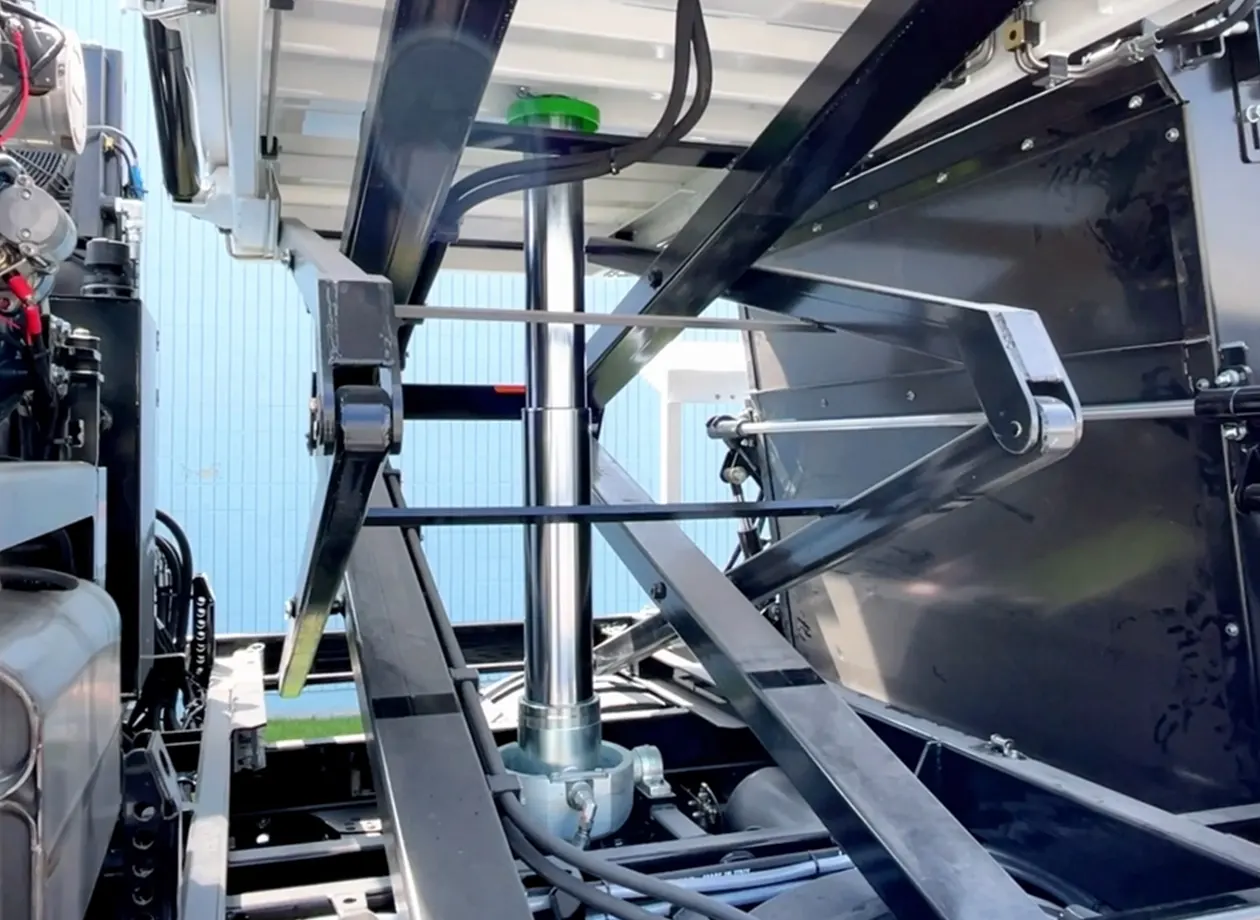

HOPPER LIFT

Our hydraulic lift system was expertly engineered to optimize weight and force, so CDL requirements stay minimal. Here’s how we do it:

A vertically mounted hydraulic cylinder bears the entire weight of the hopper and debris, leaving the scissor lift to simply balance and stabilize the load. This design puts significantly less force on the scissor lift, allowing our sweepers to have a lighter scissor assembly and increased payload capacity. To eliminate any side forces and to increase the longevity of our components, the chrome plated steel hydraulic cylinder is mounted in the cradle of the frame.

Simply put, 100% of the cylinder’s force is used to lift the hopper vertically. In comparable competitor designs, the lift cylinder applies its force at an angle to extend the scissors and lift the hopper; this is an inefficient system that only applies about 20% of the cylinder force to directly lifting the hopper, resulting in a heavier and more expensive cylinder, higher weights, and payload limitations.